J. May Equipment Group

Producing exact components for OEM manufacturers across all production volumes

Propper Mixing

Process efficiency starts with proper mixing. The performance of your mixing equipment determines how well the final product turns out and how fast production runs and how much it costs to operate your business when you combine fertilizers with oilfield chemicals and create liquid feed supplements.

Different Types of Mixing

J. May Equipment Group has spent multiple decades solving various mixing challenges. The team created operational systems which support agricultural facilities and oilfields and animal feed operations and industrial manufacturing that need specialized formulations.

The Partnership

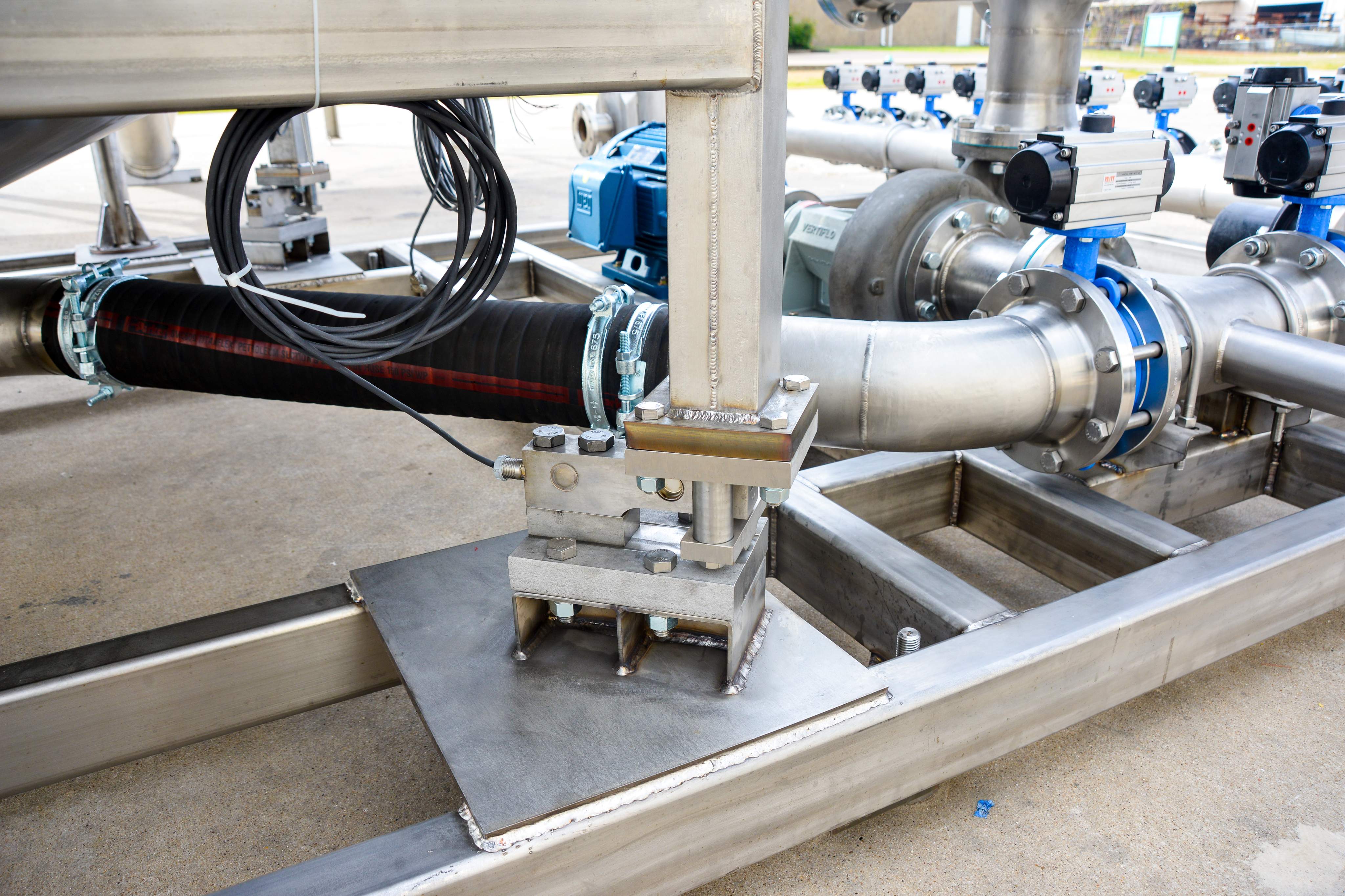

Our partnership with MSM Mechanical unites two distinct operational strengths through J. May Equipment Group’s mixing system design knowledge and MSM’s fabrication facilities. The company provides complete solutions which deliver superior performance and show verified quality to customers.